Technology Center

There are many types of suspension systems, which leaf spring design is more advantageous

Writer: Admin Time:2021-10-23 Browse:3075℃

When the vehicle runs on various roads, the road surface will produce impact load on the wheels, especially when driving at high speed on bad roads, this impact load will increase exponentially. If it is directly transmitted to the frame, the driver will feel uncomfortable, the goods will be damaged, and the parts of the vehicle will be damaged. In order to mitigate this impact, in addition to using elastic rubber tires to achieve vibration reduction, elastic suspension is also used to achieve vibration reduction.

1、 Definition of suspension

Suspension is the general name of the connecting device between the frame and the axle for transmitting all forces and moments. The force and torque transmitted between the wheel and the frame can reduce the impact of the road on the body, reduce the impact load on the body, attenuate the vibration caused by road fluctuation, and make the car run smoothly.

2、 Classification of suspension

The common elastic components in suspension include coil spring, torsion bar spring, leaf spring, air spring, rubber spring and other structural forms. At present, the market is dominated by leaf springs and air springs.

1. Leaf springs are widely used in heavy trucks and have many advantages over others:

(1) The structural design is simple, which is conducive to improving manufacturability and maintainability;

(2) It has the function of guiding, which can transfer the force and torque in all directions;

(3) The reed can make the leaf spring show linear or nonlinear elastic characteristics according to a certain combination.

2. At present, air spring is also widely used in high-end heavy trucks. The spring force generated by the elastic deformation of rubber airbag and the compressibility of air can alleviate the impact of road surface and improve the driving characteristics of vehicles.

Air springs are divided into capsule air springs, membrane air springs and composite air springs. Different from the traditional leaf spring, its elastic characteristics are nonlinear and have many advantages:

(1) High driving safety: when the vehicle passes through the concave convex Road, overtaking or sharp steering, the tension or compression stroke of the air spring is relatively large, and the stiffness increases rapidly to adjust the balance of the vehicle, so as to reduce the vibration and roll angle, improve the driving safety of the vehicle and ensure the integrity of the transported goods.

(2) Good driving comfort: due to the small internal friction of rubber and air during operation, it can absorb high-frequency vibration, produce less noise, and absorb the body vibration caused by road excitation.

(3) Long service life: the service life of air spring can reach more than 3 million times, while the service life of leaf spring is usually only about 500000 ~ 600000 times. The fatigue life of air spring is higher and the service time is longer.

(4) Strong adaptability to working conditions: for the air spring of the same model, different bearing capacity can be obtained by adjusting the internal air pressure value of the air spring to meet the requirements of various load conditions.

However, the cost of air spring suspension is nearly 10 times higher than that of ordinary leaf spring suspension. In order to reduce costs, many OEMs use leaf springs in the front suspension of some models and air springs in the rear suspension.

Because of its price advantage, leaf spring is widely used in various vehicles, especially in trucks. It can not only ensure the high reliability of suspension, but also effectively reduce the production cost of trucks.

3、 Classification of leaf springs

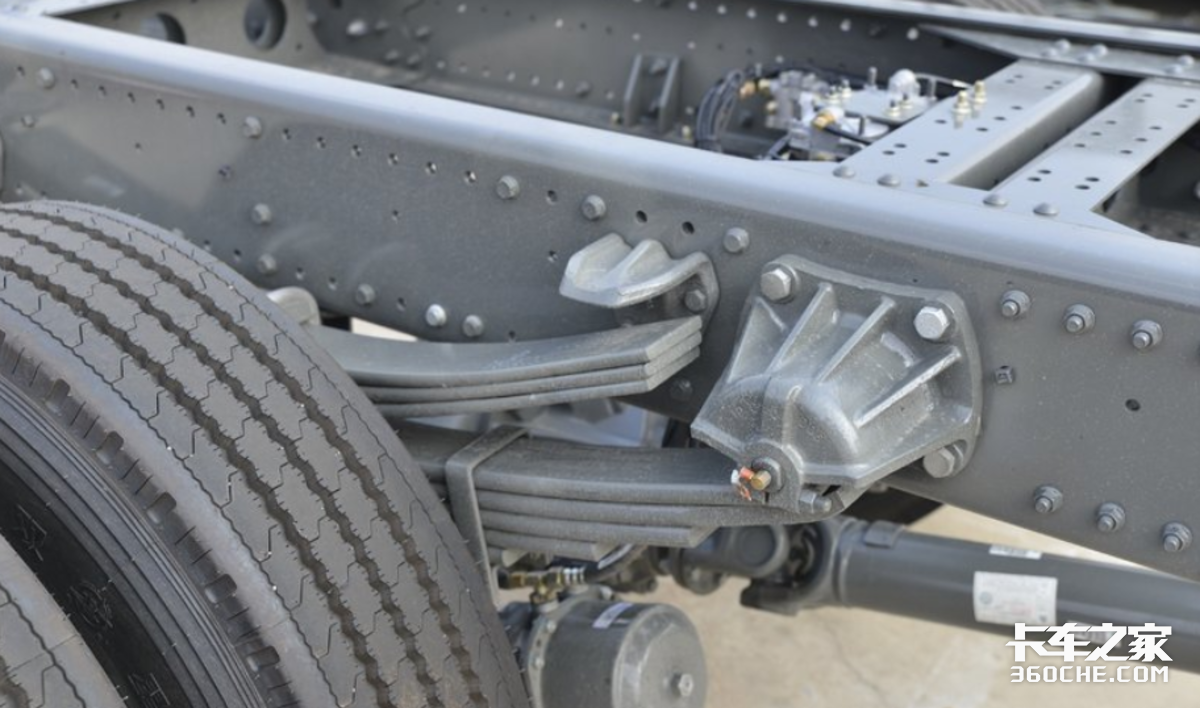

Leaf spring is the most widely used elastic element in heavy truck. It is composed of several alloy spring steel sheets with the same width but different length (thickness can be the same or different). Generally, the strength characteristics of the combined steel plate elastic storage are similar to the equal strength beam.

There are four types of commonly used automotive leaf springs: multi leaf springs, few variable cross-section leaf springs, main and auxiliary composite leaf springs and variable stiffness leaf springs.

(1) Multi leaf spring: the number of reeds is large, mostly more than 5. The thickness of the used reeds is the same, the length is different, and the elastic properties change linearly.

(2) Few leaf springs with variable cross-section: the number of springs is small, generally no more than 5. The length of the used springs is the same, the thickness changes along the length direction, and the elastic properties show a linear change.

(3) Main and auxiliary composite leaf spring: it is composed of main and auxiliary springs. When the vehicle load is small, only the main spring works. With the increase of load, the auxiliary spring and the main spring work together, and its elastic characteristics show nonlinear changes.

(4) Gradual stiffness leaf spring: the auxiliary spring is placed under the main spring, and the main spring and auxiliary spring form an integrated structure, and its elastic characteristics show nonlinear changes.

Among the above four types of leaf springs, the spring thickness of few leaf variable cross-section leaf spring is designed according to a specific law, so that the spring is in an equal stress state, so as to improve the use efficiency of spring materials and achieve the purpose of lightweight steel plate spring. It has the widest application prospect.

4、 Advantages of few variable section leaf springs

The length and width of the reed of the few leaf variable section leaf spring are the same, and the thickness changes along the horizontal direction according to a certain law. Compared with multiple equal section leaf springs, under the condition of the same performance, it has the following advantages:

(1) The stress distribution on the reed is uniform, which is similar to the equal stress beam. Compared with the traditional leaf spring, it can effectively reduce the weight by 30% - 40% and improve the allowable stress of the spring;

(2) It can reduce the dynamic stiffness of leaf spring assembly and improve the ride comfort of automobile;

(3) The damage of shot peening strengthening layer is avoided, the fatigue strength of steel plate spring can be effectively improved, and then the reliability of steel plate elastic storage can be improved;

(4) Shims with self lubrication, friction reduction and shock absorption can be added between the accumulators, which is conducive to prolonging the service life of the leaf spring.

(5) The overall thickness is reduced, which can effectively reduce the load height of the vehicle.

Conclusion: the suspension system is installed between the wheel and the frame to transmit the force and torque, reduce the impact of the road on the body, reduce the impact load on the body, and attenuate the vibration caused by road fluctuation. Compared with multiple equal section steel plates, few variable section steel plate springs have obvious advantages, light weight, good performance, high reliability and long service life, Compared with air suspension system, it has the advantage of low cost and is the first choice of truck.

CATEGORIES

LATEST NEWS

- Jining Tanzania Enterprise Cooperation Matchmaking Conference Held

- Do you know more details about friction material?

- Liangshan Shenli was selected as the champion of the 2022 municipal manufacturing single event in Jining

- Shenli company held the 4th craftsman cup theory and skill competition

- Liangshan Shenli won the honors of "Shandong famous brand" and "advanced enterprise" again

CONTACT US

Tel: +86-13792366477

Mobile: +86-13792366477

E-mail: James@chinaaxle.cn

Add: West Section of Gongming Road, Liangshan County, Jining City (Economic Development Zone)